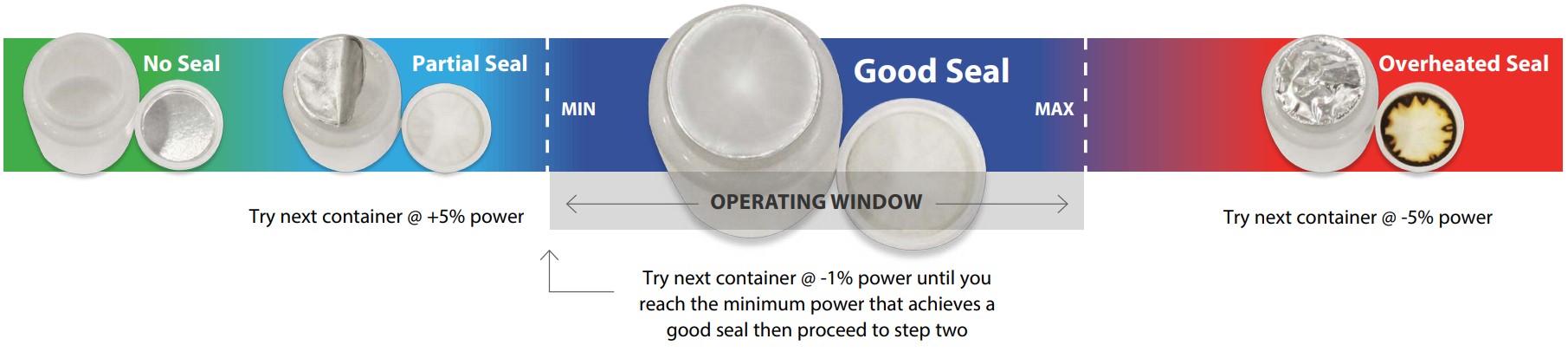

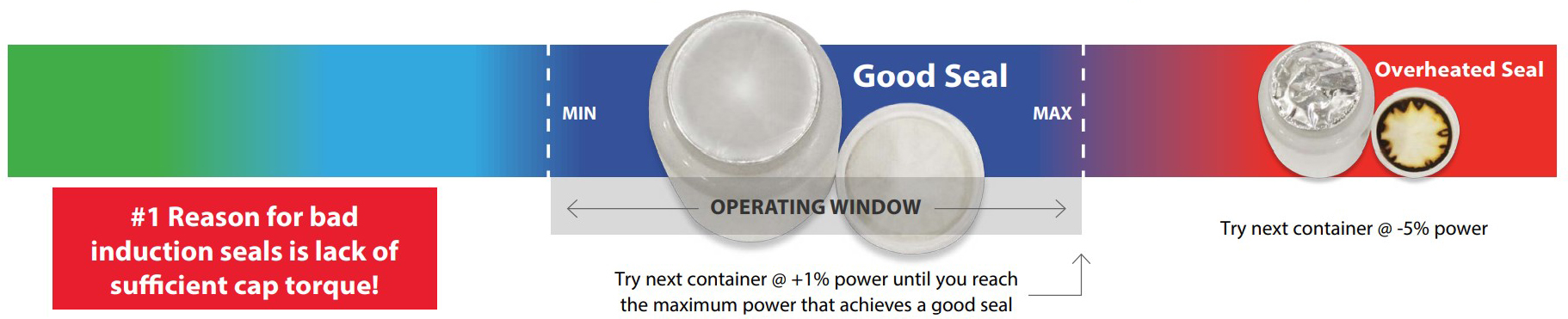

Packagers who Achieve a Perfect Seal understand the core principles of induction sealing (heat, pressure & time); ensure materials are compatible (caps, liners, bottles & products), and define the cap sealing operating window that is best for their application.

PREVENT LEAKS, PROVIDE TAMPER EVIDENCE, & PRESERVE FRESHNESS

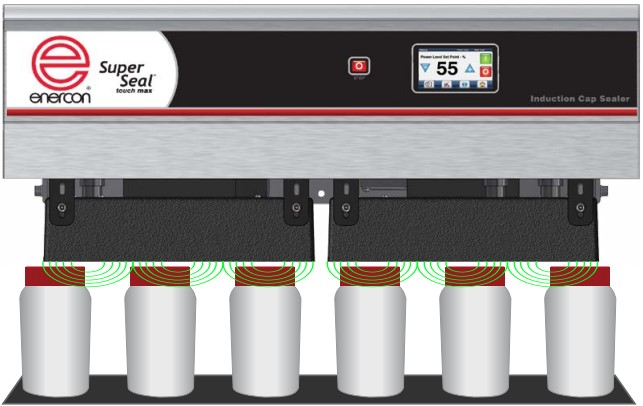

LEARN HOW INDUCTION CAP SEALERS CREATE HERMETIC SEALS

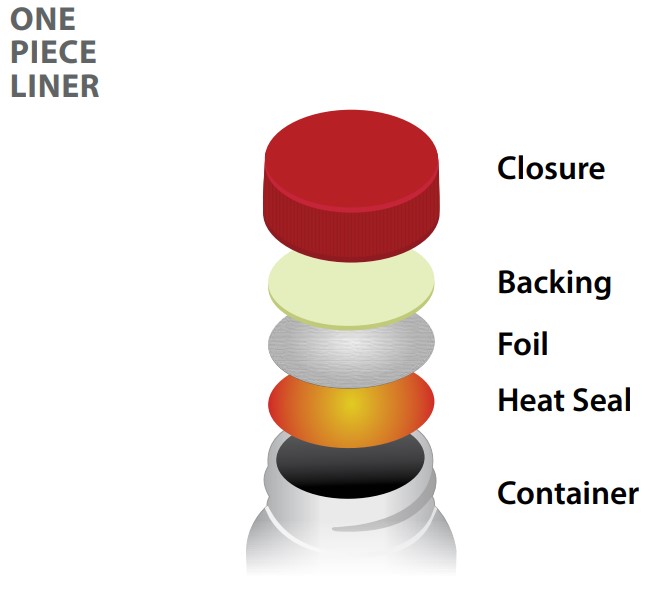

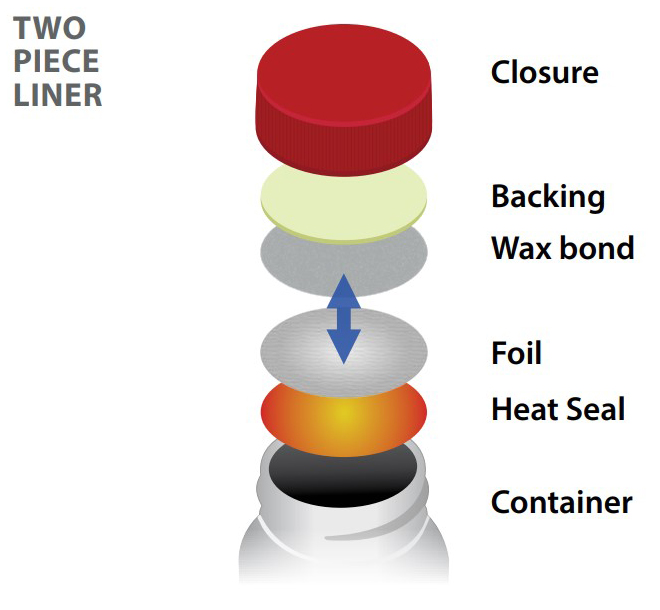

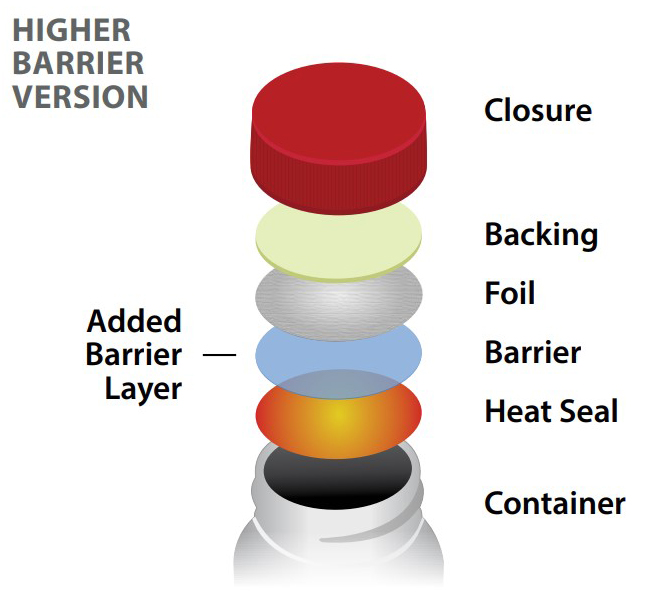

FIND OUT HOW CAPS, LINERS & CONTAINERS INTERACT

DISCOVER HOW AN OPERATING WINDOW OPTIMIZES SUCCESS

SEE CAP SEALER TECHNOLOGY AND INDUSTRY APPLICATIONS

to as two piece liners. They rely on a wax or mechanical bond between the foil liner and a foam or pulpboard backing piece which remains in the cap when it is removed.

No liner container bonding

Basic Causes

Is the sealer on?

Is there a liner in the cap?

Process/Operator Causes

What’s changed?

• Cap Torque

• Line Speed

• Power Level

• Sealing Head Gap

Material Change Causes

Liner/Container Compatibility

Supplier change

Seal is partial/weak

Process/Operator Causes

Low Application torque

Output too low/line speed too high

Caps not centered under sealing head

Caps cocked or cross threaded

Sealing head not level with conveyer

Material Causes

Saddle or ridge in land area

Liner/Container compatibility issue

Caps bottom out on shoulder of container

Seal Wrinkling

Odor

Pulp board discoloration

Foam Deforming

Cause

Too much sealing power

• Sealing output too high

• Line speed too low

• Compact yet powerful

• Set power & timer for perfect seals

• Missing foil indicator

• Base sealing head up to 83mm

• Wide sealing head up to 120mm

• Microprocessor control

• Simple push button operation

• Digital power level meter

• Local/remote power on/off mode

• Wide range of sealing heads

• The industry workhorse

• Intuitive touch screen control

• Simple set-up & operation

• Recipe management

• Supervisory password/operator lockout

• Remote start/stop & power level control

• Remote network control

• Integrated inspection & rejection available